Información Básica.

No. de Modelo.

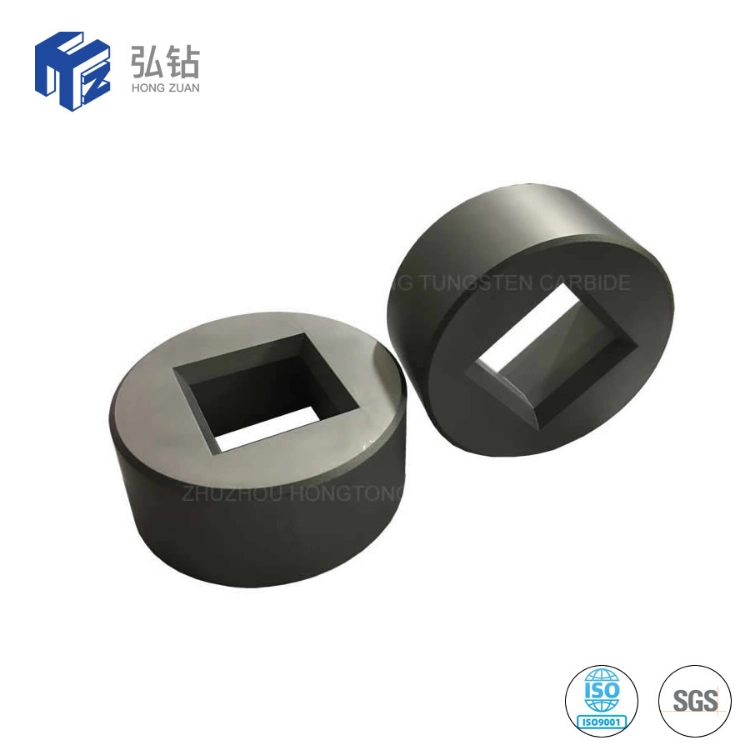

S11 S13 WTA

Tratamiento De Superficies

En blanco

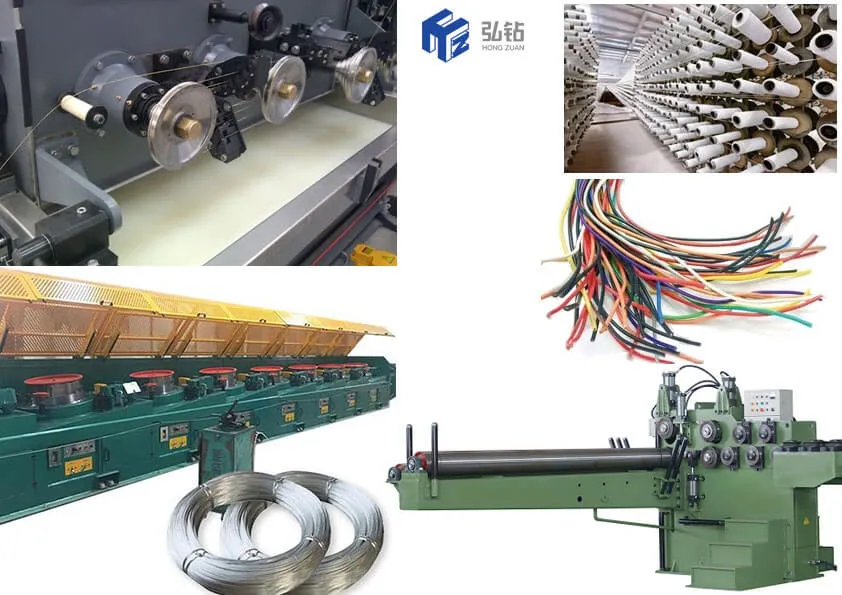

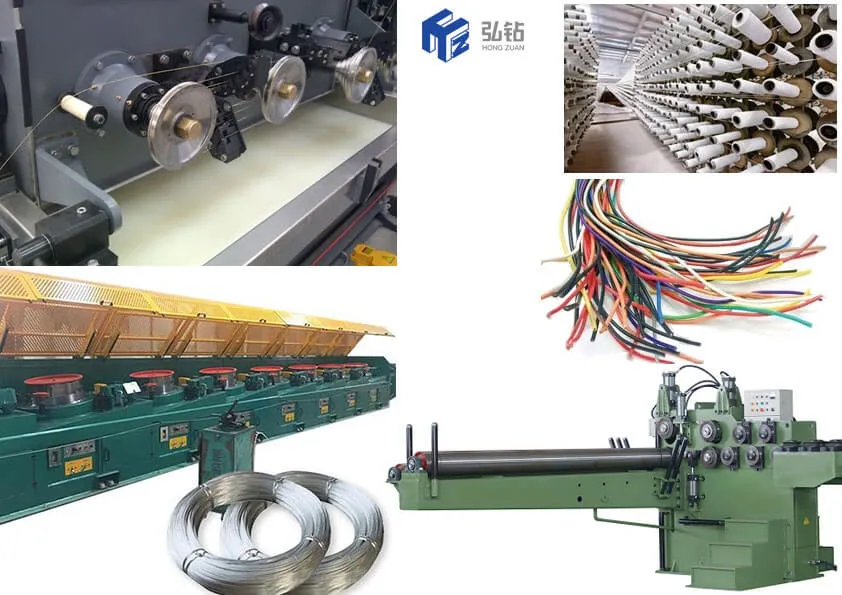

Aplicación

Ferretería, Cable Industry

Certificación

ISO

Garantía

1 Año

Personalizado

Personalizado

Paquete de Transporte

as Customer Demand

Especificación

S11 S13 WTA

Marca Comercial

HONGZUAN

Origen

Hunan, China

Código del HS

8209101900

Capacidad de Producción

20 Ton Per Month

Descripción de Producto

Feature:

2. Used in making hardware and standard stamping moulds.

3. Applicable for electronic industry, motor rotor, stator, LED lead frame, EI silicon sheet and so on.

4. Used for producing drawn mold, wear-resistant parts, stamping parts and automatic press with punch.

5. Used for stamping die, extrusion die, stamping molds.

6. Drawing many kinds of steel wire, aluminum wire, high carbon, MS wire etc

Advantage of Tungsten Carbide Dies

1. Material:100% virgin raw material with submicron grain size

2. Grade: Various grades for choice

3. Advanced production equipments and testing equipments

4. Precious Ground and polished

5. High wear resistance,high hardness and impact toughness

6. Advanced technology, automatic pressing, HIP sintering and precision grinding

7. Samples & small orders are acceptable.

For any other sizes we are able to custom-made according to clients' requirements or drawings.

Recommend grades and specifications:

Company Profile

Company Profile

ZhuZhou HongTong Tungsten Carbide Co., Ltd.,specialized in production carbide products more than 20 years and located in the hometown of tungsten carbide in China. We can manufacture all kind of tungsten carbide products. Our products are utilized in industrial, aerospace, machining, metallurgy, oil drilling, mining tools, electronic communications, construction applications. Now we are exporting to 46 countries. including USA, Russian , India , Italy, Poland ,France,Brazil etc .

ZhuZhou HongTong Tungsten Carbide Co., Ltd.,specialized in production carbide products more than 20 years and located in the hometown of tungsten carbide in China. We can manufacture all kind of tungsten carbide products. Our products are utilized in industrial, aerospace, machining, metallurgy, oil drilling, mining tools, electronic communications, construction applications. Now we are exporting to 46 countries. including USA, Russian , India , Italy, Poland ,France,Brazil etc .

We have a professional QC team follow to the System of ISO9001:2015, Covering the Raw Materials Incoming, Production Processes,Finished Products and Packaging to ensure high quality products output.

We mainly produce Tungsten Carbide Ball and Seat, Agriculture wear parts plates, Carbide tips, Carbide tiles, HPGR Stud pins, Brazed Inserts, Gripper Pads, Buttons, VSI Bars, Rod, Strips, PDC substrate, Weld on teeth, Bushings, Wire Drawing Dies, Heading Dies, Seal Ring, Nozzles, and other customized carbide products.

Product packaging

We are Factory with 20 years of production experience.

Q2: What is the producing process?

Production process including raw material cutting, machine processing, grinding, accessories cleaning, assemble, cleaning,

stoving, oil coating, cover pressing, testing, package.

Q3: How to control the products quality?

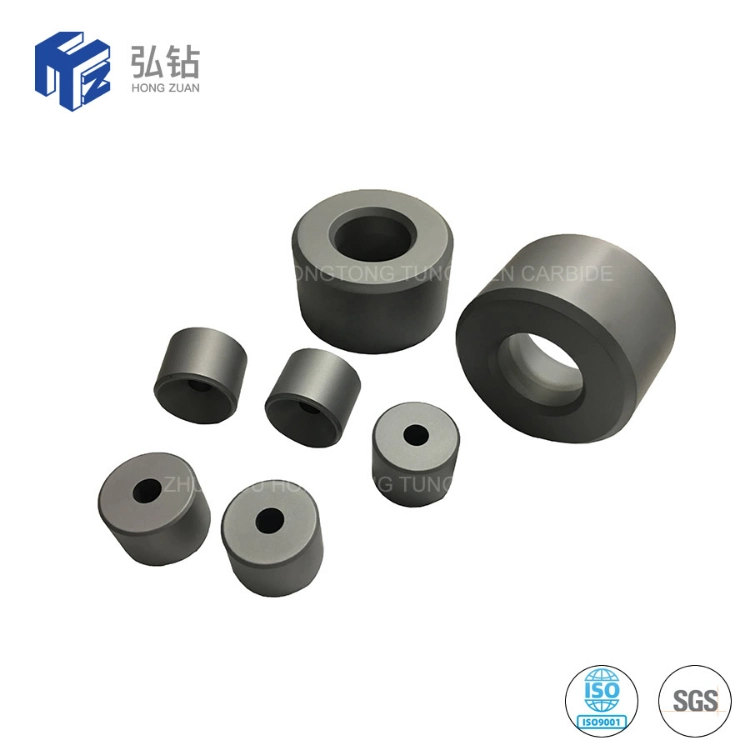

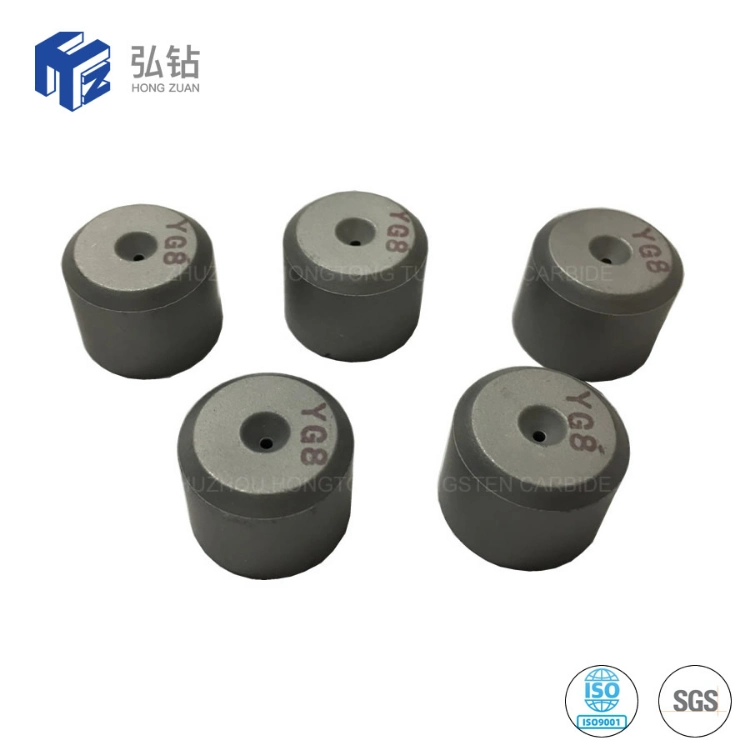

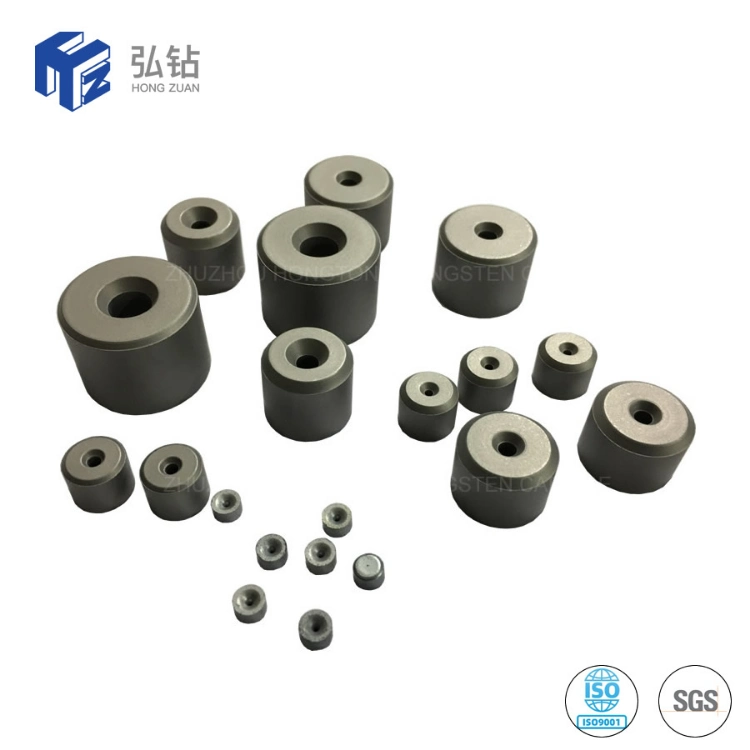

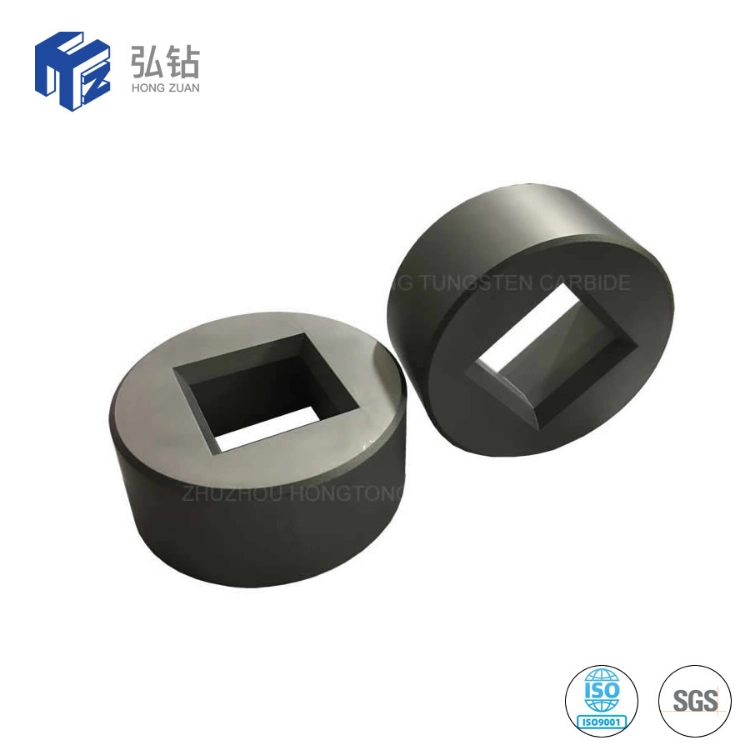

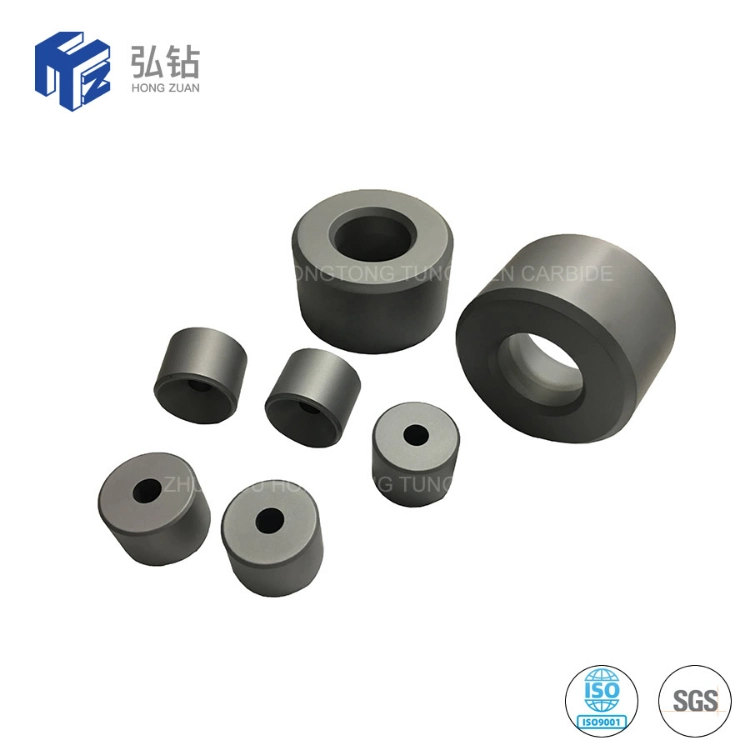

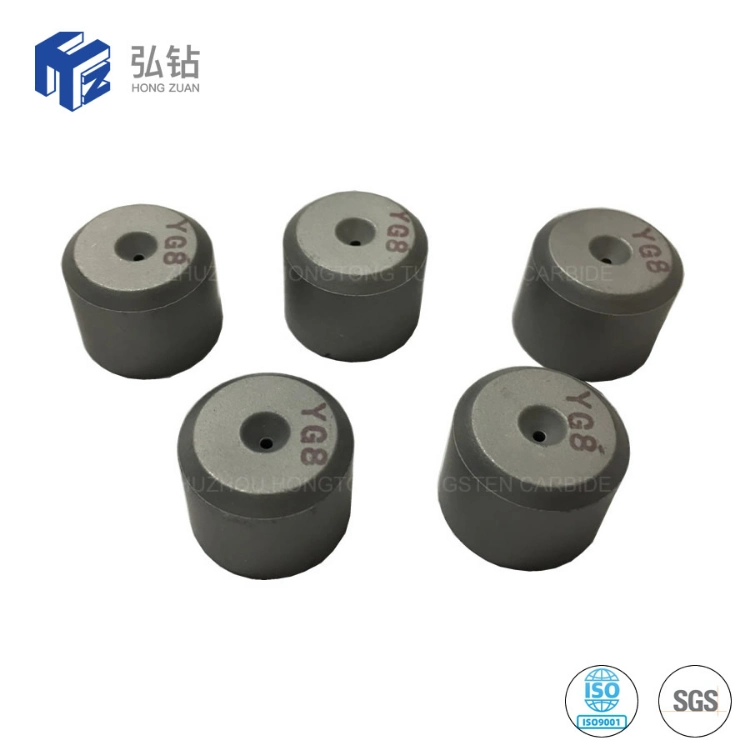

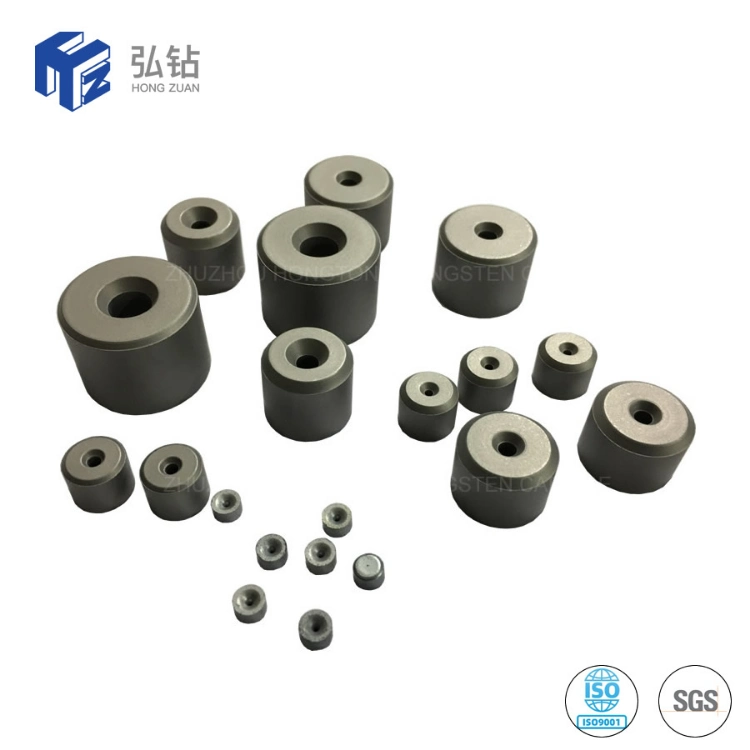

Tungsten Carbide wire drawing nibs was pressed into steel holder, to work as a wire drawing die, which was widely used in the production of wire, cable, tube, and other related products. As the parameters of tungsten carbide, the dies can last longer time and need less replacement and maintain, which make it more profitable for users. As there're many different kinds of wire/tube/rod products, there're various kinds of different wire drawing dies and nibs, including types S11 series, S12 series, S13 series, W series, WTA series, R series, etc.

1. Used for making high temperature parts, wear parts, anti-shielding parts and corrosion-resistant parts.2. Used in making hardware and standard stamping moulds.

3. Applicable for electronic industry, motor rotor, stator, LED lead frame, EI silicon sheet and so on.

4. Used for producing drawn mold, wear-resistant parts, stamping parts and automatic press with punch.

5. Used for stamping die, extrusion die, stamping molds.

6. Drawing many kinds of steel wire, aluminum wire, high carbon, MS wire etc

Advantage of Tungsten Carbide Dies

1. Material:100% virgin raw material with submicron grain size

2. Grade: Various grades for choice

3. Advanced production equipments and testing equipments

4. Precious Ground and polished

5. High wear resistance,high hardness and impact toughness

6. Advanced technology, automatic pressing, HIP sintering and precision grinding

7. Samples & small orders are acceptable.

Common shape and size check below:

| Type | D | H | d | h | α° |

| S11- | 8 | 6 | 0.3-1.0 | 0.3-0.6 | 14° |

| 10 | 8 | 0.7-1.4 | 0.3-0.6 | 14° | |

| 13 | 10 | 0.4-2.8 | 0.3-1.6 | 16° | |

| 15 | 13 | 0.5-3.0 | 0.3-1.4 | 16° | |

| 16 | 14 | 0.4-3.8 | 0.3-1.8 | 16° | |

| 20 | 17 | 1.2-4.7 | 2.0-2.6 | 18° | |

| 21 | 17 | 1.8-5.7 | 1.2-3.0 | 18° | |

| 22 | 18 | 1.7-6.4 | 1.2-3.0 | 18° |

For any other sizes we are able to custom-made according to clients' requirements or drawings.

Recommend grades and specifications:

| Grade No. | Density (g/cm3) | HRA | T.R.S (Mpa) | Application |

| YG3X | 14.9 | ≥91.5 | ≥1300 | For drawing non-ferrous metal wire and stainless-steel wire etc. |

| YG6 | 14.8 | ≥90.0 | ≥2150 | For drawing steel wire and stainless-steel wire etc. |

| YG6X | 14.8 | ≥92.0 | ≥1860 | For drawing nonferrous metal wire, steel wire, stainless steel wire. Good wear resistance and high toughness. |

| YG8 | 14.8 | ≥89.5 | ≥2320 | For drawing steel wire, stainless steel wire. Good general performance. |

| YG11 | 14.4 | ≥88.5 | ≥2420 | For fabricating drawing dies of steel tubes and rods under high compressibility ratio; punching, stamping, forging tools under large stress. |

Application:

1. Tungsten carbide with high hardness, high wear resistance and high red hardness, at 550ºC still maintain more than 56HRC hardness.

2. Has a high modulus of elasticity, generally is (4~7)×104kg / mm2, and excellent rigidity at room temperature.

3. Have a high compressive strength which is greater than 6000MPa.

4. Have good resistance to oxidation and corrosion resistance, acid resistance, alkali resistance and high temperature not easily oxidized.

5. Has a low coefficient of thermal expansion, suitable for manufacturing high, precision, sharp die.

Company Profile

Company Profile

ZhuZhou HongTong Tungsten Carbide Co., Ltd.,specialized in production carbide products more than 20 years and located in the hometown of tungsten carbide in China. We can manufacture all kind of tungsten carbide products. Our products are utilized in industrial, aerospace, machining, metallurgy, oil drilling, mining tools, electronic communications, construction applications. Now we are exporting to 46 countries. including USA, Russian , India , Italy, Poland ,France,Brazil etc .

ZhuZhou HongTong Tungsten Carbide Co., Ltd.,specialized in production carbide products more than 20 years and located in the hometown of tungsten carbide in China. We can manufacture all kind of tungsten carbide products. Our products are utilized in industrial, aerospace, machining, metallurgy, oil drilling, mining tools, electronic communications, construction applications. Now we are exporting to 46 countries. including USA, Russian , India , Italy, Poland ,France,Brazil etc . We have a professional QC team follow to the System of ISO9001:2015, Covering the Raw Materials Incoming, Production Processes,Finished Products and Packaging to ensure high quality products output.

We mainly produce Tungsten Carbide Ball and Seat, Agriculture wear parts plates, Carbide tips, Carbide tiles, HPGR Stud pins, Brazed Inserts, Gripper Pads, Buttons, VSI Bars, Rod, Strips, PDC substrate, Weld on teeth, Bushings, Wire Drawing Dies, Heading Dies, Seal Ring, Nozzles, and other customized carbide products.

Product packaging

FAQ

Q1 : Are you Factory or trading company ?We are Factory with 20 years of production experience.

Q2: What is the producing process?

Production process including raw material cutting, machine processing, grinding, accessories cleaning, assemble, cleaning,

stoving, oil coating, cover pressing, testing, package.

Q3: How to control the products quality?

All products will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Q4: What is the transportation?

If small quantity , we Suggest to send by express, such as DHL,UPS, TNT FEDEX. If large quantity, by sea.

Q5: Can you provide OEM service?

Yes, we work on OEM orders. Which means size, quantity, design, packing solution, etc will depend on your requests; and your logo will be customized on our products

Q6: How to place an order for Good performance nonstandard products by stellite alloy? 1. Fill your Order List in our online

Inquiry System (Also you can directly contact our salesperson by E-mail / Skype / Whats App) 2. We will make a feedback to you ASAP after receive your order list.

Q7: What's your delivery time ?

For the normal type which we have mold it takes 7-15 days after receiving the advance payment. For the non standard which we do not have mold it takes 15-35 days after receiving the advance payment.

Q8:How to contact us?

You can Contact me by E-mail, Trademanager, Skype, Mobile, whatsapp and so on

Q4: What is the transportation?

If small quantity , we Suggest to send by express, such as DHL,UPS, TNT FEDEX. If large quantity, by sea.

Q5: Can you provide OEM service?

Yes, we work on OEM orders. Which means size, quantity, design, packing solution, etc will depend on your requests; and your logo will be customized on our products

Q6: How to place an order for Good performance nonstandard products by stellite alloy? 1. Fill your Order List in our online

Inquiry System (Also you can directly contact our salesperson by E-mail / Skype / Whats App) 2. We will make a feedback to you ASAP after receive your order list.

Q7: What's your delivery time ?

For the normal type which we have mold it takes 7-15 days after receiving the advance payment. For the non standard which we do not have mold it takes 15-35 days after receiving the advance payment.

Q8:How to contact us?

You can Contact me by E-mail, Trademanager, Skype, Mobile, whatsapp and so on